SPA Modules

Tileable shower seat

Tileable shower seat

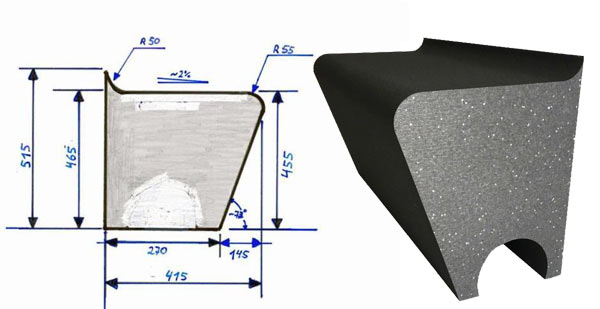

According to customer drawing, this shower seat was produced.

Most often, the shower seat is mounted in the self-construction. Simply glue in the prefabricated shower bench (e.g. with assembly foam), cross-link, seal with the shower and then tile with the shower.

Advantages of EPS modular construction

- quickly built up (no bricklaying and dusting)

- easy to edit or change

- Cost-effective (as a lot of working time is eliminated).

See here the construction progress……

Tileable shower seat – here you can see the processes for installing a tileable shower seat in the shower. EPS shower seats for tiling are robust, easy to work with and offer pleasant comfort in the shower.

- Glue EPS shower seat

The shower seat is most often mounted in the self-construction. To do this, glue the seat to all parts of the wall with mounting foam. After that, this is cross-linked with fiberglass mesh (textile glass mesh/facade mesh).

2. seal shower

Seal the entire shower according to the waterproofing manufacturer’s information (1k or 2k waterproofing). This waterproofing is applied 2x, especially for steam showers.

At the bottom you put sealing tapes and even complete waterproofing membranes.

3. tiles of the shower

After the waterproofing dries, you can start tiling.

4. shower is ready tiled

The work was worth it! Finally sitting in the shower!

Production made in Austria – in Pregarten Upper Austria!

Do you like this post “Steam shower with shower seat” and the possibilities of our EPS modules?

We look forward to your comment and sharing this post on Facebook, Google, Twitter and Co.